Flying Heavy: How DASA-funded UAS Revolutionises Military Logistics

With the help of DASA funding, ISS Aerospace developed a 600kg heavy-lift unmanned aerial system (UAS) capable of carrying 250kg payloads

- The innovation features a unique hybrid turbine generator power system that eliminates the need for complex electrical recharging infrastructure in the field

- DASA’s Defence Technology Exploitation Programme (DTEP) provided critical funding that enabled ISS to create this technology

- Successfully trialled in 2025, this project represents the first completed DTEP project

From Ship to Shore in Minutes

On naval vessels around the world, the same time-consuming scene plays out daily: crew members transfer supplies between ships or from ship to shore using small boats, manual labour, and helicopter support. This process can be slow, resource-intensive, and vulnerable to disruption from weather conditions.

Now picture a different scenario: an unmanned aerial system takes flight from a ship, automatically lands on a waiting pallet of supplies, autonomously secures its load without human intervention, and lifts off – delivering cargo to shore in a fraction of the traditional time - and then - heads back to the ship for more supplies.

With the help of DASA funding, this vision of automated logistics is becoming reality thanks to Newbury-based ISS Aerospace and their revolutionary heavy-lift drone system, funded through DASA’s Defence Technology Exploitation Programme (DTEP).

Funded by DASA: ISS Aerospace UAS Flight Test

The Innovation: Power and Payload

ISS Aerospace’s system represents a significant leap forward in unmanned aerial capabilities. At 600kg total weight, it can carry a remarkable 250kg payload – equivalent to two fully-equipped soldiers – with flight times currently at 35-40 minutes.

“The innovation is three-pronged,” explains Ryan Kempley, CEO, and founder of ISS Aerospace. “First, it is a super heavy-lift UAS, which itself is quite unique. Second, we’ve brought across our heritage of super reliable, super safe systems. Third, and the main reason DTEP funded this project was because of our unique turbine power plant that powers the system”.

The innovation’s standout feature is its hybrid turbine generator power system. Rather than relying on traditional battery packs that require complex and frequent recharging infrastructure, ISS Aerospace developed a system that uses efficient aviation fuel.

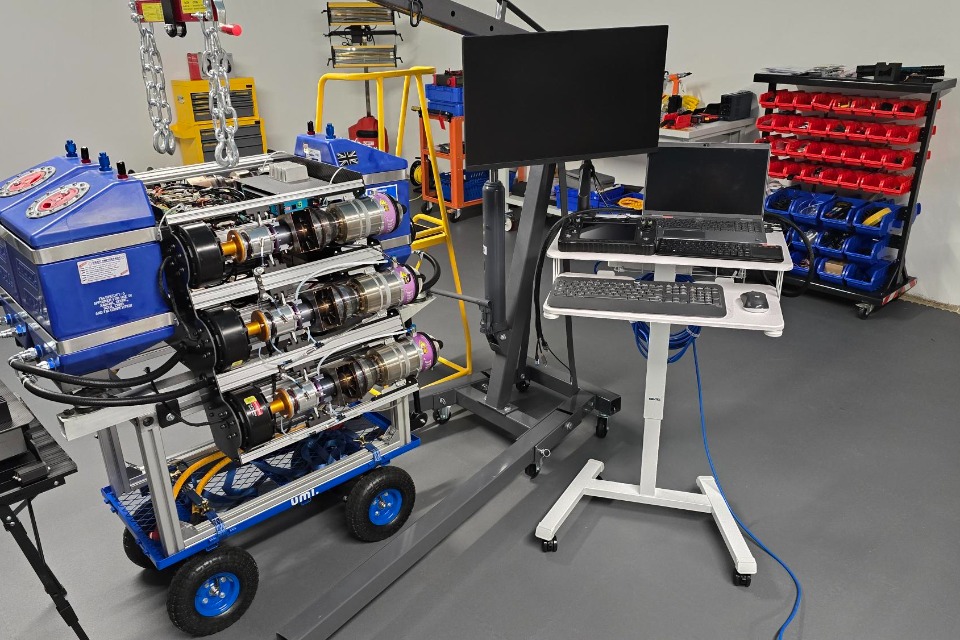

The hybrid turbine generator power system

“Our UASs fly around at 100 to 120 kilowatts, so they need a lot of power,” Kempley explains. “You can buy auxiliary power unit (APU) turbine generators off the shelf, but they’re extremely expensive – in the hundreds of thousands of pounds – and very heavy, around 100+ kilos.”

ISS’s solution repackages high-end micro gas turbines with hybrid battery technology to create their own 100-kilowatt generator at a fraction of the cost and weight of conventional systems.

Engineering Challenges and Breakthroughs

Creating this power system required solving complex engineering challenges. The team developed sophisticated control systems to maintain perfect balance between turbine power generation and battery usage.

“If we charge the battery too fast, problems happen. If we deplete the battery too fast, problems happen,” notes Kempley. “But we came out with something that essentially means if all the turbines die, we still keep flying. If the battery dies and the turbines are running, we still keep flying. If one or two turbines die, we still keep flying. It’s very robust in terms of resilience.”

This level of reliability is crucial for military logistics operations where failure could compromise mission-critical supplies.

The system already outperforms competitors in its class, but ISS has identified further enhancements. “We’ve already identified a new supporting turbine that takes us up to around 3-3.5 hours of flight,” Kempley notes.

Transforming Military Logistics

In the competitive landscape of heavy-lift drones, ISS has positioned itself in a unique category. Below their 250-300kg payload capability sits systems carrying 60-100kg, while above them are much larger single-rotor helicopters or fixed-wing aircraft that are around the size of shipping containers.

The potential military applications are significant, particularly for naval logistics. The system can be used for last-mile ship-to-ship and ship-to-shore transport, where Kempley notes “90% of stores between ships or even on last-mile logistics are below 150 kilos.”

Further enhancing its capabilities, ISS recently won another MOD contract under Project Morrigan to develop a universal payload release mechanism, allowing the drone to automatically pick up and deliver cargo without human intervention.

“You just land on top of your package on the deck and then take off again. You’re done. There’s no unloading or loading,” explains Kempley. “When you get to that stage, it’s many multiples quicker than current methods.”

DTEP: Making Innovation Possible

For ISS Aerospace, DASA’s DTEP funding was transformative. Founded ten years ago, the company has evolved from a small commercial business into a growing enterprise with 14 staff, projected to reach 22 by year’s end – all through organic growth.

“Developing that kind of turbine system and UAS is costly – raw materials alone are a couple hundred thousand pounds, plus hundreds of hours of man-time,” Kempley emphasises. “As a small company, we could never have afforded to just go out and decide to develop this UAS. It would have been impossible without DTEP.”

DTEP’s emphasis on commercialisation and post-project success has been particularly valuable for the SME. “There’s a lot more emphasis on commercialisation, what we’re going to do afterwards and how we’re going to make it successful”, Kempley notes.

From Concept to Flight

Funded back in September 2023, this represents the first completed DASA DTEP project, highlighting the programme’s ability to bring innovative concepts to reality quickly.

The project recently culminated in successful test flights of the UAS, proving the design, and gaining valuable in-flight data, with a further demonstration planned to showcase the complete system to stakeholders. Next steps also include cosmetic additions to the platform, such as a cowling (a removable engine cover) and testing and improvement to the control and power systems before the V1 system is rolled out to end users later in 2025.

The ISS Aerospace team with the UAS

For a company that began in commercial applications before gradually expanding into defence, DASA’s support has been instrumental in enabling growth and technological advancement. ISS now balances its business with approximately 60-70% defence work and 30-40% commercial applications.

As drones continue revolutionising military logistics, ISS Aerospace’s innovation stands to transform how supplies move between ships and shore – making operations faster, more efficient, and ultimately more effective in supporting forces on the ground.